Custom Features

Depending on your application, we can build your industrial blender to be standard-duty, heavy-duty, or extra-heavy-duty using 316 stainless steel, 304 stainless steel, mild steel, or other types and grades of steel. Contact surfaces can be low bacteria finish, mirror finish, near mirror finish, #4, or 2B to achieve a nutraceutical/pharma-grade, food-grade, or chemical-grade standard finish.

Standard 2-B Finish

Near-Mirror Finish

Low Bacteria-Mirror Finish

Optional Equipment Features

Don’t compromise on performance, get exactly what you need with our custom and optional features. Depending on your blending application, we can build your industrial mixer with your choices of almost any combination of our custom features below to meet your company's specific blending needs.

Some of our optional features include:

- Exterior finished can be a professional looking matte finish, or a mirror finish

- Blenders can be constructed in a standard duty, heavy duty, or extra heavy duty

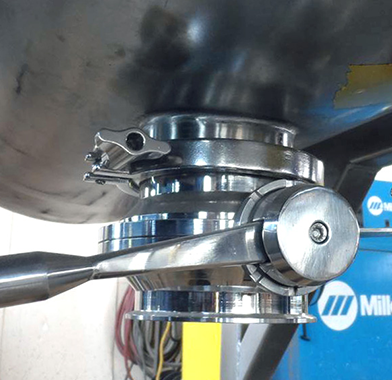

- Discharges can be a slide gate, butterfly valve, ball valve, or bomb bay doors

- Holes in lids for overhead hoppers

- Lift kits for low overhead applications

- Inlet dust collection nipples

- Liquid injection systems and tank

- QA sample port in discharge chute

- Blender loading platforms or mezzanines

- Stainless or mild steel frames

- Pneumatic discharge openers

- Leg lengths can be customized

- Variable frequency drives for rpm control

- Discharge dust collection ports

- Magnets custom fitted to discharge

- Bulk bag hanging systems

- Heating and cooling jackets

- End or center bottom discharges

- Multiple discharge openings

Click On Photos To Enlarge